The Job Shop

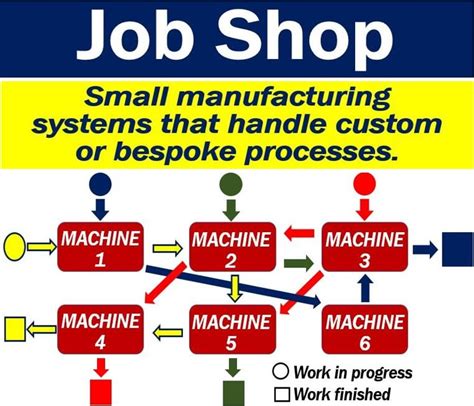

In the world of manufacturing and production, efficiency and flexibility are key to staying competitive. Enter the concept of the Job Shop, a dynamic and innovative approach to production that has revolutionized the way businesses operate. The Job Shop model offers a unique and adaptable solution, allowing companies to thrive in a rapidly changing market. In this comprehensive guide, we will delve into the intricacies of the Job Shop, exploring its history, key principles, and the immense benefits it brings to the modern manufacturing landscape.

The Evolution of the Job Shop: A Brief History

The origins of the Job Shop can be traced back to the early days of industrial revolution, where the concept of specialized, small-scale production emerged. Initially, these job shops were characterized by their ability to undertake a variety of small-batch manufacturing tasks, catering to diverse customer needs. Over time, with advancements in technology and a shift towards customization, the Job Shop model evolved to become a pivotal part of the manufacturing ecosystem.

In the 20th century, the Job Shop gained prominence as a vital link in the supply chain, particularly for industries like aerospace, automotive, and electronics. The ability to handle complex, unique orders with precision and speed made Job Shops indispensable. However, it was with the advent of computerization and digital technologies that the Job Shop truly came into its own.

Today, the Job Shop stands as a testament to the power of adaptability and precision. With the integration of advanced machinery, real-time data analytics, and a highly skilled workforce, the modern Job Shop can efficiently handle a myriad of tasks, from prototyping to large-scale production runs. Its ability to swiftly adapt to changing market demands and customer requirements sets it apart from traditional manufacturing models.

The Core Principles of a Job Shop

At its core, a Job Shop operates on a set of fundamental principles that differentiate it from other manufacturing approaches.

Flexibility and Adaptability

One of the defining features of a Job Shop is its inherent flexibility. Unlike mass production facilities that are geared towards producing a single product in large quantities, Job Shops are designed to accommodate a wide range of products and services. This flexibility allows them to quickly adjust to market fluctuations, changes in customer preferences, or sudden shifts in demand.

For instance, a Job Shop might receive orders for customized machinery parts one day, and the next, they could be producing limited-edition consumer goods. This ability to pivot and adapt is crucial in today's dynamic market, where consumer trends and preferences can change rapidly.

Specialization and Expertise

Job Shops are known for their deep specialization and technical expertise. They often house a diverse range of machinery and equipment, catering to various manufacturing processes. From precision machining and fabrication to advanced 3D printing and laser cutting, Job Shops have the capabilities to deliver complex, high-quality products.

The skilled workforce in Job Shops is another critical aspect. Employees are trained to operate a variety of machinery and often have specialized knowledge in specific manufacturing techniques. This level of expertise ensures that the Job Shop can handle intricate, detail-oriented tasks with precision and efficiency.

Lean Manufacturing and Efficiency

The Job Shop model is inherently aligned with the principles of lean manufacturing. By optimizing processes, minimizing waste, and maximizing efficiency, Job Shops can deliver products at competitive prices without compromising on quality. This lean approach ensures that resources are utilized effectively, leading to reduced lead times and improved overall productivity.

For example, Job Shops often employ just-in-time inventory management, ensuring that raw materials and components are procured only when needed. This not only reduces storage costs but also minimizes the risk of excess inventory becoming obsolete.

Benefits of the Job Shop Model

The Job Shop model offers a multitude of advantages to businesses and industries, making it an attractive choice for a wide range of manufacturing needs.

Enhanced Customer Satisfaction

Job Shops excel at delivering customized, tailored solutions to meet specific customer requirements. Whether it’s a unique product design, a specific material preference, or a tight deadline, Job Shops can adapt their processes to ensure customer satisfaction. This level of flexibility and customization is highly valued by businesses looking to differentiate their offerings in a competitive market.

Moreover, the quick turnaround times and efficient processes of Job Shops mean that customers receive their products faster, leading to improved customer relationships and increased loyalty.

Cost-Effectiveness and Scalability

Despite the specialized nature of their work, Job Shops often offer cost-effective solutions. By optimizing processes, minimizing waste, and utilizing advanced technologies, Job Shops can produce high-quality goods at competitive prices. This is particularly beneficial for small to medium-sized businesses that may not have the capital to invest in large-scale manufacturing facilities.

Additionally, the scalability of Job Shops is a significant advantage. They can easily scale their operations up or down depending on the demand, making them an ideal choice for businesses with fluctuating production needs. Whether it's a small batch of prototypes or a large-scale production run, Job Shops can adjust their capacity accordingly.

Quality Assurance and Consistency

Maintaining high-quality standards is a priority for Job Shops. With their specialized equipment and skilled workforce, Job Shops can deliver products that meet or exceed customer expectations. Rigorous quality control processes ensure that every product, regardless of its complexity or customization, is produced to the highest standards.

Furthermore, Job Shops often have robust systems in place to ensure consistency across all products. Whether it's a one-off custom order or a large-volume production run, the end result is a product that consistently meets the defined specifications.

Innovation and Technological Integration

Job Shops are at the forefront of technological innovation in manufacturing. They embrace advanced technologies, from computer-aided design (CAD) and manufacturing (CAM) to robotics and automation. By integrating these technologies into their processes, Job Shops can enhance their precision, efficiency, and overall productivity.

For instance, the use of CAD/CAM software allows Job Shops to quickly and accurately produce detailed product designs, while robotics and automation can handle repetitive tasks with speed and precision. This integration of technology not only improves the quality of the final product but also reduces the overall production time.

The Future of Job Shops

As we move further into the digital age, the role and importance of Job Shops are only set to increase. With the rise of Industry 4.0 and the Internet of Things (IoT), Job Shops will continue to evolve and adapt, leveraging the power of data analytics and automation to enhance their operations.

The integration of smart technologies will enable Job Shops to optimize their processes even further, reducing waste, improving efficiency, and enhancing overall productivity. Moreover, with the increasing focus on sustainability and circular economy practices, Job Shops can play a pivotal role in promoting eco-friendly manufacturing processes and reducing environmental impact.

In conclusion, the Job Shop model offers a flexible, efficient, and highly adaptable approach to manufacturing. Its ability to cater to diverse customer needs, coupled with its focus on quality, innovation, and sustainability, positions it as a key player in the modern manufacturing landscape. As businesses continue to navigate a dynamic market, the Job Shop stands as a reliable and innovative solution, ensuring their competitive edge in the years to come.

How do Job Shops handle complex, customized orders?

+Job Shops are equipped with advanced machinery and a highly skilled workforce, allowing them to tackle complex customization requirements. They employ a range of manufacturing processes, from precision machining to 3D printing, ensuring that even the most intricate designs can be brought to life. Their ability to adapt quickly to unique specifications is a key advantage over traditional manufacturing models.

What industries benefit most from Job Shop services?

+Job Shops are particularly beneficial for industries that require customization, quick turnaround times, and small-to-medium batch production. This includes sectors like aerospace, automotive, electronics, and medical devices. Job Shops can handle the unique requirements of these industries, ensuring high-quality products are delivered efficiently.

How do Job Shops ensure quality control and consistency?

+Job Shops have robust quality control systems in place to ensure that every product meets or exceeds defined specifications. This includes rigorous inspection processes, both during and after production. They also employ advanced technologies like computer-aided inspection (CAI) to ensure precision and consistency across all products, regardless of their complexity.