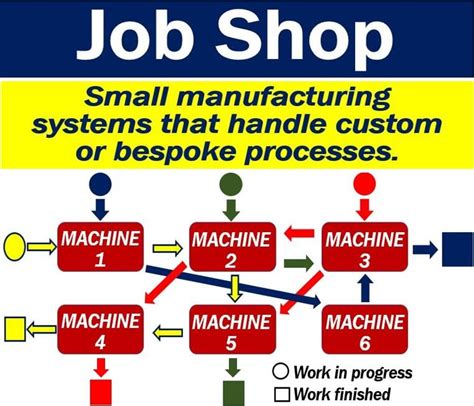

Job Shop

In the ever-evolving landscape of manufacturing and production, the term "Job Shop" holds a significant place, offering a unique and adaptable approach to industrial processes. This article delves into the intricate world of Job Shops, exploring their historical context, operational strategies, and their enduring relevance in the modern manufacturing sector. By examining the key aspects of Job Shop operations, we uncover the advantages and challenges they present, shedding light on their vital role in the industry.

The Evolution and Significance of Job Shops

Job Shops have a rich history dating back to the early days of industrialization. They emerged as a response to the demand for customized, low-volume production, providing an alternative to the traditional mass production methods. Over time, Job Shops have evolved, incorporating advanced technologies and efficient management practices to stay competitive in a rapidly changing market.

The core principle of a Job Shop revolves around flexibility and adaptability. Unlike continuous production lines or assembly plants, Job Shops specialize in handling small-batch, diverse production orders. This makes them ideal for industries that require quick turnarounds, customization, or unique product specifications.

Understanding the Job Shop Model

At the heart of a Job Shop’s success is its ability to manage a variety of projects simultaneously. This model is characterized by its non-repetitive nature, where each project or “job” is unique, often with its own set of specifications, timelines, and resources. The flexibility to switch between jobs efficiently is a key differentiator, allowing Job Shops to cater to diverse client needs.

Key Components of Job Shop Operations

- Job Order Management: Job Shops excel at managing multiple job orders, ensuring each project is completed within the specified time frame and budget. This involves meticulous planning, scheduling, and coordination of resources.

- Skilled Workforce: A key strength of Job Shops is their skilled workforce. Employees are often cross-trained to handle various tasks, allowing for efficient job transitions and ensuring the highest quality of work.

- Equipment Versatility: Job Shops invest in versatile machinery and equipment. This enables them to adapt quickly to different production requirements, reducing downtime between jobs.

- Customization Expertise: With their focus on customization, Job Shops often develop specialized skills in areas like product design, engineering, and rapid prototyping.

| Key Advantage | Description |

|---|---|

| Flexibility | Job Shops can accommodate diverse product lines, offering rapid responses to market demands and client requirements. |

| Customization | They excel in producing customized, low-volume products, a niche that many larger manufacturers cannot efficiently serve. |

| Rapid Turnaround | The non-linear production process allows for quick adjustments, leading to faster project completion times. |

Challenges and Strategies in Job Shop Management

Despite their advantages, Job Shops face unique challenges. Managing multiple, diverse projects simultaneously requires efficient resource allocation and careful planning. Additionally, the focus on customization can lead to longer lead times and higher costs if not managed effectively.

Addressing Challenges Through Innovative Solutions

Modern Job Shops are embracing digital technologies to streamline their operations. Enterprise Resource Planning (ERP) systems, for instance, offer comprehensive solutions for managing job orders, tracking inventory, and controlling production processes. By integrating ERP with other digital tools, Job Shops can optimize their workflows, enhance communication, and improve overall efficiency.

The Role of Data Analytics

Data-driven decision-making is becoming increasingly crucial for Job Shops. By analyzing production data, they can identify bottlenecks, optimize processes, and make informed choices about resource allocation. This analytical approach also helps in forecasting demand, ensuring Job Shops can plan their operations strategically.

| Challenges | Strategies |

|---|---|

| Resource Management | Implement ERP systems for better resource allocation and tracking. Utilize data analytics to optimize production processes. |

| Customization Costs | Develop efficient design and prototyping processes. Explore automation for repetitive tasks to reduce costs. |

| Market Competition | Focus on niche markets and unique product offerings. Build strong client relationships for repeat business. |

The Future of Job Shops: Staying Competitive

As the manufacturing industry continues to evolve, Job Shops must adapt to stay competitive. Embracing digital transformation, investing in skilled talent, and focusing on continuous improvement are key strategies for future success.

Digital Transformation for Efficiency

Digital technologies offer immense potential for Job Shops to streamline their operations and enhance productivity. From implementing Industry 4.0 solutions to leveraging advanced analytics, Job Shops can revolutionize their processes, reducing costs and improving lead times.

Investing in Skilled Talent

In the era of automation and digital technologies, the role of skilled workers remains crucial. Job Shops must invest in training and development programs to ensure their workforce is equipped with the skills needed to operate advanced machinery and leverage digital tools effectively.

Focus on Continuous Improvement

The manufacturing industry is known for its relentless pursuit of efficiency and quality. Job Shops must embrace a culture of continuous improvement, adopting lean manufacturing principles and implementing Six Sigma methodologies to enhance their operational excellence.

Conclusion: The Enduring Relevance of Job Shops

In a world driven by customization and rapid innovation, Job Shops offer a unique and invaluable service. Their ability to adapt, innovate, and deliver customized solutions keeps them at the forefront of the manufacturing industry. By embracing digital technologies, investing in skilled talent, and focusing on continuous improvement, Job Shops are poised to thrive in the dynamic landscape of modern manufacturing.

What distinguishes a Job Shop from other manufacturing models?

+Job Shops are characterized by their flexibility and ability to handle diverse, low-volume production orders. Unlike mass production or assembly lines, Job Shops specialize in customization and rapid turnaround, making them ideal for industries with unique product specifications.

What are the key challenges faced by Job Shops?

+Job Shops often face challenges related to resource management, as they must juggle multiple, diverse projects. Additionally, the focus on customization can lead to longer lead times and higher costs if not managed efficiently. Market competition is also a challenge, as Job Shops often compete with larger manufacturers.

How can Job Shops leverage digital technologies for improvement?

+Digital technologies offer Job Shops the opportunity to streamline operations and enhance productivity. By implementing ERP systems, leveraging data analytics, and adopting Industry 4.0 solutions, Job Shops can optimize their processes, reduce costs, and improve lead times.