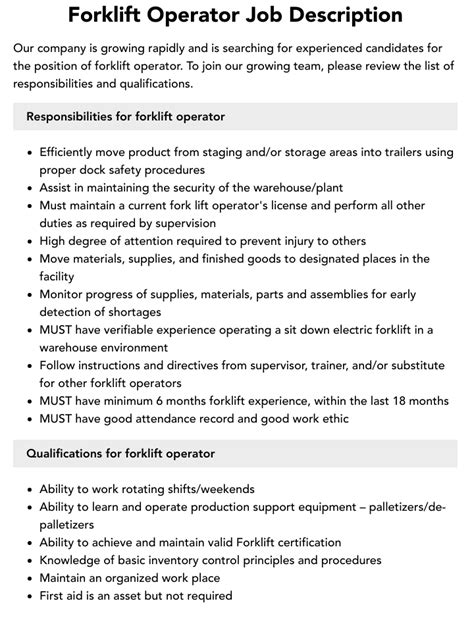

Forklift Operator Job Description

The role of a forklift operator is crucial in various industries, especially in logistics, manufacturing, and warehousing. These skilled professionals play a vital role in ensuring the smooth flow of operations by efficiently moving and handling materials with precision and safety. With a wide range of responsibilities, from operating heavy machinery to maintaining inventory accuracy, forklift operators are an indispensable part of modern supply chain management.

Forklift Operator: A Detailed Role Overview

A forklift operator’s primary duty is to operate a powered industrial truck, commonly known as a forklift, to lift, move, stack, and transport materials in a safe and efficient manner. This job requires a high level of skill, attention to detail, and a deep understanding of both the equipment and the work environment. Beyond simply driving the forklift, operators must possess the knowledge and ability to handle various types of loads, navigate through tight spaces, and maintain a safe work environment.

Key Responsibilities and Daily Tasks

The daily tasks of a forklift operator are diverse and demanding. They are responsible for receiving and interpreting work orders, loading and unloading goods from trucks or storage areas, and carefully placing items in designated locations. Additionally, they must conduct regular inspections of their equipment to ensure it is in optimal working condition. This includes checking for any signs of damage, leaks, or malfunctions that could pose a safety risk.

Safety is paramount in this role. Operators must adhere to strict safety protocols at all times, including wearing the appropriate personal protective equipment (PPE) and conducting pre-operation safety checks. They are also responsible for identifying and reporting any potential hazards in the workplace, ensuring a proactive approach to safety management.

Technical Skills and Abilities

Forklift operators need a unique set of technical skills to perform their job effectively. They must be able to operate different types of forklifts, including electric, diesel, and propane-powered models, each with its own unique characteristics and operating procedures. This requires a deep understanding of the machinery, its capabilities, and its limitations.

Furthermore, operators must possess excellent spatial awareness and judgment. They need to accurately estimate load weights, center of gravity, and clearances to avoid accidents or damage to goods. This skill is particularly important when maneuvering in tight spaces or when stacking goods at different heights.

| Technical Skill | Description |

|---|---|

| Forklift Operation | Proficiency in driving and maneuvering various types of forklifts. |

| Load Assessment | Ability to accurately estimate load weights and center of gravity. |

| Spatial Awareness | Excellent judgment in navigating tight spaces and stacking goods. |

| Equipment Maintenance | Conduct regular inspections and basic maintenance on forklifts. |

| Safety Protocols | Adhere to and enforce strict safety guidelines at all times. |

Qualifications and Training

To become a forklift operator, individuals typically need to obtain a Forklift Operator Certification. This certification is a legal requirement in many countries and ensures that operators have the necessary skills and knowledge to operate forklifts safely. The certification process usually involves both theoretical and practical assessments, covering topics such as forklift operation, safety procedures, and load handling.

In addition to certification, many employers prefer or require candidates to have previous experience in a similar role. This experience can provide valuable insights into the practical aspects of the job and help operators adapt quickly to different work environments.

The Impact of Forklift Operators on Modern Industries

The work of forklift operators has a significant impact on the efficiency and productivity of modern industries. In logistics and distribution centers, for instance, operators play a critical role in the timely and accurate movement of goods, ensuring that products reach their destinations without delay. In manufacturing, they contribute to the smooth flow of materials, facilitating just-in-time production processes.

Benefits and Challenges

One of the key benefits of being a forklift operator is the opportunity for growth and advancement within the field. With experience and additional certifications, operators can progress to more specialized roles, such as trainer or supervisor. They can also explore opportunities in different industries, as the skills acquired are transferable across various sectors.

However, the job also comes with its challenges. Operators often work in physically demanding conditions, requiring them to be fit and able to withstand long hours of standing, walking, and operating heavy machinery. They must also be mentally alert at all times, as the job involves a high level of responsibility and the potential for serious accidents if safety protocols are not followed.

Future Prospects and Technological Advancements

The future of forklift operation is likely to be influenced by technological advancements. The integration of automation and robotics in material handling is expected to grow, with the development of autonomous forklifts and advanced safety systems. While this may change the nature of the job, it also presents new opportunities for operators to adapt and develop their skills in line with technological progress.

Furthermore, with the increasing focus on sustainability and green technologies, there is a growing demand for operators skilled in operating electric or hybrid forklifts. These environmentally friendly alternatives are becoming more prevalent in industries aiming to reduce their carbon footprint, offering new avenues for skilled forklift operators to contribute to sustainable practices.

What are the typical working hours for a forklift operator?

+

Forklift operators often work full-time hours, which can include shifts during the day, evening, or night, depending on the operational needs of the facility. This may include weekends and holidays as well.

What are the physical demands of this job?

+

The job requires a certain level of physical fitness, as operators need to be able to stand for extended periods, lift and carry items, and maneuver the forklift in sometimes tight spaces. A basic level of fitness is necessary to perform these tasks safely and effectively.

How can one stay updated with the latest safety protocols and regulations in forklift operation?

+

Continuous learning is crucial in this field. Operators should regularly attend safety training sessions, workshops, and seminars to stay informed about the latest industry standards and best practices. Many organizations also provide ongoing training to ensure their operators are up-to-date with safety guidelines.